As an Amazon Associate, I earn from qualifying purchases

If you own a Ford F150 or are thinking about getting one, you might have come across the term “Iwe.” But what exactly is an Iwe on a Ford F150, and why does it matter to you?

Understanding this can save you time, money, and a lot of frustration. You’ll discover what an Iwe is, how it affects your truck, and why knowing about it can make your driving experience smoother. Keep reading to get the full picture and take control of your Ford F150 like a pro.

Iwe Basics

The IWE on a Ford F150 is a special part of the truck’s transfer case. It helps control power to the front wheels. Understanding the IWE basics helps you know how your truck works in different conditions.

This system is important for driving on slippery or rough roads. It allows the truck to switch between two-wheel and four-wheel drive smoothly. Knowing how the IWE works can help you maintain your vehicle better.

What Does Iwe Stand For?

IWE means “Integrated Wheel End.” It is part of the four-wheel drive system. The IWE controls the front axle’s locking and unlocking. This lets the front wheels turn or stay still depending on the road.

How The Iwe Works

The IWE uses a small electric motor inside the front axle. When activated, it locks the front wheels to the axle. This makes the front wheels turn with the drive shaft. It helps the truck get better traction on tough surfaces.

Why The Iwe Is Important

The IWE improves fuel efficiency by unlocking the front axle when not needed. It also reduces wear on parts by only locking the wheels when necessary. This system helps your truck handle different driving situations safely and smoothly.

Purpose Of Iwe

The IWE on a Ford F150 plays an important role in the truck’s 4WD system. It controls how the front wheels connect to the drivetrain. This helps the truck handle different road conditions better. The IWE makes the shift between two-wheel drive and four-wheel drive smooth and automatic.

Understanding the purpose of the IWE helps in knowing how your truck works. It also helps in diagnosing issues related to the 4WD system.

Engaging Four-wheel Drive When Needed

The IWE activates the front axle only when extra traction is needed. This means the truck runs in two-wheel drive under normal conditions. The IWE automatically engages four-wheel drive on slippery or rough surfaces. This keeps the truck stable and improves grip without driver input.

Improving Fuel Efficiency

Since the IWE disconnects the front wheels during two-wheel drive, it reduces drag. Less drag means the engine uses less fuel. This helps save fuel during everyday driving. The IWE balances power and efficiency by switching off the front axle when not needed.

Protecting The Drivetrain Components

The IWE prevents damage by controlling when the front wheels engage. It avoids unnecessary wear on parts like the front differential and axle shafts. By engaging only when needed, it extends the life of drivetrain components. This reduces repair costs and keeps the truck reliable.

Iwe Components

The IWE on a Ford F150 is a key part of the truck’s drivetrain. It helps control power between the front and rear wheels. The system improves traction and driving in tough conditions. Understanding the IWE components gives insight into how this system works. Each piece plays a role in managing wheel engagement.

These parts work together to switch between two-wheel and four-wheel drive. The system activates or deactivates the front axle based on driving needs. Let’s explore the main components that make up the IWE system.

Iwe Actuator

The IWE actuator is an electric motor. It controls the locking and unlocking of the front hubs. This motor receives signals from the truck’s control module. It then moves the gears inside the hub to engage or disengage the front wheels.

Hub Assembly

The hub assembly contains gears and locking mechanisms. It connects the wheel to the axle shaft. When the actuator moves the gears, the hub locks or unlocks. This allows the front wheels to either rotate freely or receive power.

Control Module

The control module manages the IWE system’s operation. It monitors wheel speed, traction, and driver input. Based on this data, it sends commands to the actuator. This ensures smooth and timely engagement of the front hubs.

Wiring Harness

The wiring harness links the control module to the actuator. It carries electrical signals needed for the IWE system. Proper wiring ensures reliable communication and system function. Damaged wires can cause the IWE to fail or act erratically.

Credit: www.amazon.com

How Iwe Works

IWE on a Ford F150 means In-Wheel Electronics. It controls brakes and traction in each wheel. This helps improve safety and handling.

The Integrated Wheel End (IWE) on a Ford F150 helps control the front axle’s locking system. It lets the truck switch between two-wheel drive and four-wheel drive. This system improves traction on slippery or rough surfaces.

The IWE uses a small electric motor. This motor moves gears inside the wheel hub. When activated, it locks the front wheels to the axle. This allows power to flow to both front wheels.

The system receives signals from the vehicle’s transfer case. When four-wheel drive is selected, the IWE motor engages. It pushes a locking collar to connect the wheel hub to the axle shaft.

When four-wheel drive is off, the IWE motor retracts the collar. This disconnects the wheel hub from the axle. The front wheels then spin freely, reducing wear and improving fuel efficiency.

The IWE also has sensors. They confirm if the hubs are locked or unlocked. This information is sent to the dashboard display for the driver.

This system works automatically but can be manually overridden if needed. It provides better control and traction without driver hassle.

Benefits Of Iwe On F150

The IWE (Increased Wheel End) on a Ford F150 offers several important benefits. It improves the truck’s performance and durability. Many F150 owners find these advantages helpful for both daily driving and tough tasks.

Understanding these benefits helps you see why IWE is valuable. It supports better handling, protects parts, and can reduce maintenance costs.

Enhanced Off-road Capability

The IWE system helps the truck handle rough terrain better. It locks the front wheels when needed. This improves traction on dirt, mud, and rocks. The F150 becomes more capable in off-road conditions.

Improved Fuel Efficiency

IWE reduces drag by disconnecting the front wheels. The truck uses less energy when driving on smooth roads. This can lead to better gas mileage. You spend less money on fuel over time.

Lower Wear And Tear

The system reduces stress on front drivetrain parts. It prevents unnecessary rotation of parts when not needed. This lowers the chance of damage and wear. Your F150 lasts longer with fewer repairs.

Smoother Driving Experience

IWE reduces noise and vibration from the front wheels. The ride feels smoother, especially on highways. This adds comfort for daily driving and long trips.

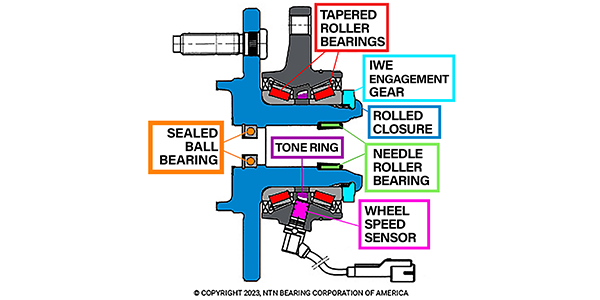

Credit: www.brakeandfrontend.com

Common Iwe Issues

The Integrated Wheel End (IWE) on a Ford F150 helps control the four-wheel drive system. It locks and unlocks the front wheels to improve traction. Despite its benefits, the IWE can face several common issues. These problems affect driving performance and can lead to costly repairs if ignored.

Recognizing these issues early saves time and money. Here are some typical problems you might see with the IWE on your Ford F150.

Failure To Engage Or Disengage

The IWE may fail to lock or unlock the front wheels. This problem causes poor traction on slippery roads. It often happens due to electrical or mechanical faults inside the IWE unit.

Signs include a clicking noise or a warning light on the dashboard. This issue can make driving difficult in rough conditions.

Air Leak In The Pneumatic System

The IWE uses air pressure to operate. An air leak in the system stops it from working properly. Leaks cause the IWE to stay locked or unlocked unexpectedly.

Check hoses and fittings for cracks or damage. Repairing leaks restores the IWE’s normal function.

Worn Or Damaged Components

Parts inside the IWE, like gears and seals, wear out over time. Damage leads to slipping or noise from the front axle. This wear reduces the IWE’s effectiveness and can cause failure.

Regular inspection helps catch wear before it becomes serious.

Electrical Connection Problems

Bad wiring or connectors can stop the IWE from working. Corrosion or loose wires cause intermittent or no signal to the unit. This issue results in the IWE not responding to commands.

Cleaning and securing connections often fix this problem quickly.

Diagnosing Iwe Problems

Diagnosing IWE problems on a Ford F150 helps keep your truck running well. The IWE, or Integrated Wheel End, controls the locking of the front hubs. When it fails, the truck may lose four-wheel drive or show warning lights. Finding the exact issue early saves time and money.

Check For Warning Lights And Error Codes

Start by looking at your dashboard for any warning lights. The four-wheel-drive or IWE light often signals a problem. Use an OBD-II scanner to read error codes. These codes point to specific issues in the IWE system. Clear codes after repair to see if the problem returns.

Listen For Unusual Noises

Noise from the front wheels can hint at IWE trouble. A grinding or clicking sound during engagement shows wear or damage. Drive slowly and pay attention to sounds when switching to four-wheel drive. Odd noises mean the IWE may need inspection or replacement.

Inspect The Iwe Vacuum System

The IWE uses vacuum to lock and unlock the hubs. Check vacuum lines for cracks, leaks, or disconnections. Test the vacuum actuator with a hand pump or gauge. Poor vacuum pressure stops the IWE from working properly. Fix leaks or replace faulty parts to restore function.

Test The Hub Lock Mechanism

Physically check the front hubs by trying to turn the wheels by hand. Locked hubs should not spin freely. If they do, the IWE might be stuck or broken. Remove the hub cover to inspect gears and seals. Replace damaged parts to ensure proper locking.

Consult A Professional For Complex Issues

Some IWE problems require special tools or skills. A mechanic can perform deeper tests and repairs. They can also reset the system after fixing it. Professional help ensures the IWE works smoothly and your truck stays safe.

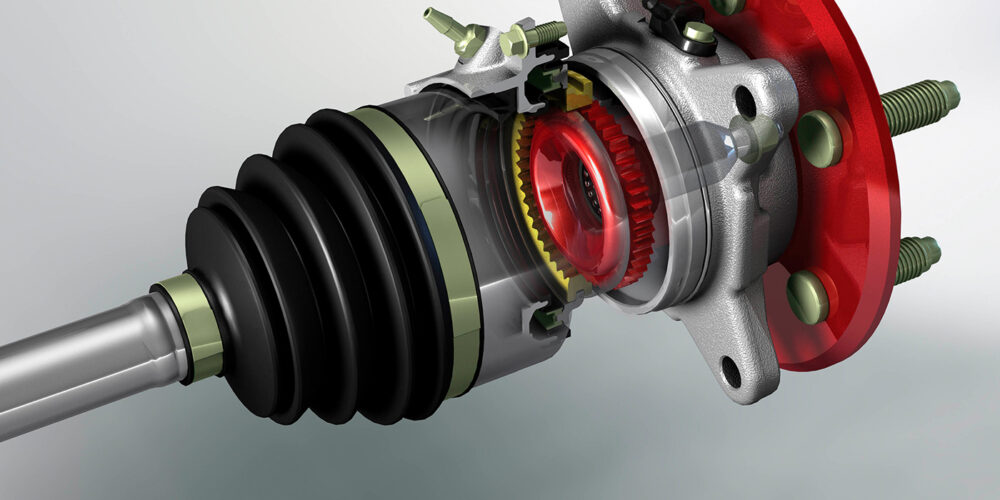

Credit: www.tomorrowstechnician.com

Repairing Iwe System

The IWE system on a Ford F150 helps control the front axle locking. It improves traction by locking the front wheels when needed. Repairing the IWE system keeps the truck running smoothly off-road and on slippery roads.

Fixing an IWE system involves checking electrical parts and mechanical components. Proper diagnosis is important to find the exact problem. Some repairs can be done at home with basic tools. Other issues may need a professional mechanic.

Identifying Common Iwe Problems

Common IWE issues include failure to lock or unlock the front axle. You may hear clicking sounds or notice a warning light. Sometimes, the system stays locked, making turning difficult. These signs point to electrical or mechanical faults.

Testing Electrical Components

Start by checking fuses and wiring for damage. Use a multimeter to test voltage at the IWE solenoid. Faulty wiring or blown fuses stop the system from working. Replace damaged parts to restore power to the IWE system.

Fixing Mechanical Faults

Mechanical issues often involve the actuator or gears inside the hub. Dirt, rust, or wear can block movement. Clean and lubricate parts to improve function. Replace broken components to ensure reliable locking and unlocking.

Resetting The Iwe System

After repairs, reset the system to clear error codes. Disconnect the battery for a few minutes or use a scan tool. Resetting helps the truck recognize the fixed parts. This step prevents false warnings and improves system response.

Iwe Maintenance Tips

Maintaining the Iwe on a Ford F150 helps keep your truck running smoothly. Regular care prevents issues and saves money on repairs. Small checks can improve performance and extend the Iwe’s life.

Check Iwe Connections Regularly

Loose or dirty connections cause poor Iwe function. Clean the connectors with a soft brush. Tighten any loose wires to ensure good contact. Do this every few months or after rough drives.

Keep The Iwe Clean

Dirt and dust affect the Iwe’s performance. Use a dry cloth to wipe the surface gently. Avoid water or chemicals that could damage parts. Clean it during routine truck washes.

Inspect For Damage

Look for cracks or worn areas on the Iwe. Replace damaged parts quickly to avoid bigger problems. A visual check every month helps catch issues early.

Use The Right Tools

Always use tools made for automotive electronics. Wrong tools can harm the Iwe or truck wiring. Follow the Ford manual instructions for maintenance tasks.

Schedule Professional Checks

Have a mechanic inspect the Iwe during regular truck service. Experts find hidden problems and fix them properly. Schedule this once or twice a year for peace of mind.

Upgrading Iwe Features

Upgrading the IWE (Integrated Wheel End) on a Ford F150 improves its performance and control. It allows the driver to manage the four-wheel drive system better. Enhanced IWE features bring stronger durability and smoother operation.

These upgrades help the vehicle handle rough roads and tough conditions. They also reduce noise and wear on the drivetrain. Upgrading is a smart choice for those who use their F150 often off-road or in harsh weather.

Better Engagement And Disengagement

New IWE units engage and disengage faster than older models. This means the four-wheel drive activates smoothly. The shift happens without clunks or delays, improving driving comfort.

Improved Durability

Upgraded IWEs use stronger materials and better seals. This protects the system from dirt and water damage. It also extends the lifespan of the parts, reducing repair costs.

Quieter Operation

Modern IWE upgrades focus on reducing noise during use. The mechanism works quietly, minimizing distracting sounds inside the cabin. This makes driving more pleasant, especially on highways.

Easier Maintenance

Newer IWE designs make maintenance simpler. They allow easier access for checks and repairs. This saves time and effort for owners and mechanics alike.

Frequently Asked Questions

What Does Iwe Stand For On A Ford F150?

IWE stands for Integrated Wheel End, a part of the truck’s 4WD system.

How Does The Iwe Work On A Ford F150?

It engages or disengages the front wheels to switch between 2WD and 4WD modes.

Why Is The Iwe Important For Ford F150 Trucks?

It helps save fuel and reduces wear by disconnecting front wheels when 4WD is off.

What Problems Can Occur With The Iwe On A Ford F150?

Common issues include noisy operation, failure to engage, or leaking seals.

How To Know If The Iwe Is Failing On A Ford F150?

You may hear clicking noises or notice the front wheels not engaging properly.

Can I Drive A Ford F150 With A Bad Iwe?

It’s possible but not recommended, as it may cause further damage to the drivetrain.

How Much Does It Cost To Repair An Iwe On A Ford F150?

Repair costs range from $200 to $600 depending on parts and labor.

Can I Replace The Iwe Myself On A Ford F150?

Basic mechanical skills help, but special tools and knowledge are often needed for safe replacement.

How To Maintain The Iwe On A Ford F150?

Regular inspection and changing the front differential fluid help keep it working well.

Is Iwe Found On All Ford F150 Models?

No, only certain model years and trims with 4WD have the IWE system.

Conclusion

An IWE on a Ford F150 helps control exhaust flow. It improves engine performance and sound. Many drivers find it useful for towing and power. It is a simple device but makes a difference. Knowing what an IWE does can help you decide.

It fits well with other truck upgrades. Understanding its role keeps your Ford running smooth. Consider it if you want better exhaust control. Small changes can lead to better driving experience.

As an Amazon Associate, I earn from qualifying purchases