As an Amazon Associate, I earn from qualifying purchases

Auto glass is essential for vehicle safety. But how is it made?

In this blog post, we will explore the fascinating process behind auto glass manufacturing. From raw materials to the final product, each step is crucial. Understanding this process can help you appreciate the technology and craftsmanship involved. Auto glass is not just ordinary glass.

It must be strong, clear, and safe. The journey begins with selecting the right materials. Then, the glass undergoes various treatments to enhance its strength and durability. This includes heating, cooling, and layering. Each phase ensures the glass can withstand impacts and protect passengers. By the end of this post, you’ll have a clearer picture of how auto glass is made and why it’s so important.

Credit: www.autoglass-atlanta.com

Introduction To Auto Glass

Auto glass is a crucial component in vehicles. It provides safety, protection, and comfort. Understanding how it is made can help us appreciate its role in our daily lives.

Importance Of Auto Glass

Auto glass protects passengers during accidents. It prevents injuries from flying debris. It also supports the vehicle’s structure. This helps maintain the car’s integrity.

Auto glass also ensures clear visibility. It shields from wind, rain, and harmful UV rays. This makes driving safer and more comfortable.

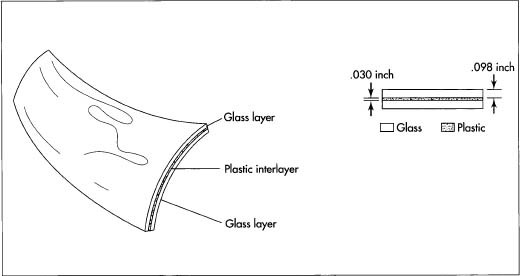

Common Types

There are two main types of auto glass: laminated and tempered. Laminated glass is commonly used for windshields. It consists of two glass layers with a plastic layer in between. This design prevents shattering.

Tempered glass is used for side and rear windows. It is heated and then rapidly cooled. This process makes it stronger and causes it to break into small, harmless pieces.

Raw Materials

Auto glass is a vital part of your vehicle’s safety. Understanding how it is made can be fascinating. The process begins with the right raw materials. Let’s delve into the essential components that make up auto glass.

Sand And Silica

Sand is a key ingredient in auto glass. Specifically, high-purity silica sand. This sand is heated at high temperatures. The heat turns the sand into a molten state. This molten sand is the base for glass.

Silica is another crucial component. It comes from quartz. Silica helps in forming the glass structure. It gives the glass its strength. Both sand and silica play a major role in the glass-making process.

Additional Components

Besides sand and silica, other materials are needed. Lime is one of them. Lime improves the glass’s durability. It also makes the glass more resistant to water.

Soda ash is another ingredient. It lowers the melting point of the silica. This helps in shaping the glass. Without soda ash, the process would be more energy-intensive.

Colorants can also be added. They give the glass a tint. This can reduce glare from the sun. It also adds to the aesthetic appeal of the vehicle.

These raw materials are mixed in precise amounts. The mixture is then heated. The result is a strong, clear piece of auto glass.

Glass Manufacturing Process

The glass manufacturing process is a fascinating journey. It transforms raw materials into durable auto glass. This process involves several stages. Each stage is crucial for creating high-quality glass. Understanding these stages helps appreciate the craftsmanship behind your car’s windshield.

Melting Stage

The melting stage is the first step in making auto glass. Here, raw materials are combined and heated. These materials include silica sand, soda ash, and limestone. The mixture is heated in a furnace. The temperature reaches around 1700°C (3092°F). The intense heat melts the raw materials into a liquid form.

This molten glass is the foundation. It must be free of impurities. Any contaminants can weaken the glass. Skilled technicians monitor the melting process. They ensure the glass mixture is perfect.

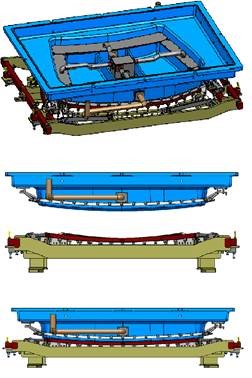

Forming Stage

In the forming stage, the molten glass takes shape. This stage is vital for creating the glass sheet. The liquid glass is poured onto a flat surface. This surface is often a bath of molten tin. The glass spreads evenly over the tin. This process is called the Float Glass Process.

The glass cools as it floats on the tin. It forms a flat, even sheet. The thickness of the glass is controlled here. Technicians use rollers to adjust the glass thickness. This stage ensures the glass is uniform and smooth.

The forming stage also includes cutting the glass. The glass sheet is cut into desired sizes. These pieces will later become car windows or windshields. Precision is key. Each piece must fit perfectly in its frame.

Tempering Auto Glass

Tempered auto glass is stronger than regular glass. It is also safer. It shatters into small, dull pieces instead of sharp shards. This process involves heating and rapid cooling. Let’s explore each step.

Heating Process

The first step in tempering auto glass is heating. The glass is placed in a furnace. This furnace heats the glass to more than 600 degrees Celsius. The high temperature makes the glass soft. It is now ready for the next step.

Rapid Cooling

After heating, the glass goes through rapid cooling. This process is also called quenching. High-pressure air blows on both surfaces of the glass. The outer surfaces cool quickly. The inner part cools more slowly. This difference in cooling rates makes the glass stronger.

Tempered glass can handle a lot of stress. It is four to five times stronger than untreated glass. This makes it ideal for car windows. Safety and durability are key in auto glass production. Tempering helps achieve both.

Laminated Safety Glass

Laminated safety glass is a type of auto glass that enhances safety. It has two layers of glass bonded together by a plastic layer. This plastic layer is known as the interlayer. The process of making laminated safety glass involves several steps.

Pvb Interlayer

The interlayer used in laminated safety glass is polyvinyl butyral (PVB). PVB is a clear, flexible plastic. It helps hold the glass layers together. The PVB interlayer also prevents the glass from shattering into sharp pieces. This makes laminated safety glass much safer.

Bonding Process

In the bonding process, the glass and PVB layers are pressed together. High heat and pressure are applied to bond the layers. This creates a strong, durable piece of laminated glass. The bonding process ensures the glass can withstand impacts. It also makes the glass resistant to penetration.

Quality Control

Quality control is crucial in the auto glass manufacturing process. It ensures that the glass meets safety standards and performs well under stress. This section covers the main methods used for quality control.

Inspection Techniques

Inspection techniques help identify defects in auto glass. Workers use various tools and methods to check the glass. Visual inspections are common. Workers look for cracks, chips, and other flaws. They also check for uniform thickness.

Machines also play a role. Automated systems scan the glass for defects. They can detect flaws that the human eye might miss. This improves the accuracy of inspections.

Stress Testing

Stress testing evaluates the glass’s strength. It simulates conditions the glass might face in real life. For example, machines apply pressure to the glass. This tests its ability to withstand impacts.

Another method involves temperature changes. The glass is heated and then cooled rapidly. This checks its resistance to thermal stress. These tests ensure the glass can handle extreme conditions.

Both inspection techniques and stress testing are key in producing safe auto glass. They ensure that the final product is reliable and durable.

Environmental Considerations

Auto glass production has seen significant advancements over the years. Today, manufacturers prioritize sustainability and environmental impact. This shift helps reduce the carbon footprint of the auto industry. Here are some key environmental considerations in auto glass production.

Recycling Efforts

Recycling plays a crucial role in auto glass manufacturing. Broken or damaged glass is not wasted. It is collected and processed for reuse. This recycling reduces the need for raw materials. It also lowers energy consumption. Recycled glass keeps waste out of landfills. This contributes to a cleaner environment.

Energy Efficiency

Energy efficiency is another critical factor. Modern production methods use less energy. Innovations in technology have made this possible. Efficient furnaces and machinery are now standard. These improvements reduce greenhouse gas emissions. Energy-efficient practices also cut operational costs. This benefits both the environment and manufacturers.

Credit: en.wikipedia.org

Credit: www.madehow.com

Frequently Asked Questions

What Materials Are Used To Make Auto Glass?

Auto glass is made from silica, soda ash, and limestone. These materials ensure strength and clarity.

How Is Auto Glass Tempered?

Auto glass is heated to high temperatures and then rapidly cooled. This process makes it stronger and safer.

What Is Laminated Auto Glass?

Laminated auto glass consists of two layers of glass with a plastic layer in between. It prevents shattering.

Why Is Auto Glass Important For Safety?

Auto glass protects passengers from debris and keeps the vehicle’s structure intact during accidents. Essential for safety.

Can Auto Glass Be Recycled?

Yes, auto glass can be recycled. It is often used in making new glass products or fiberglass insulation.

How Is Auto Glass Installed In Vehicles?

Auto glass is installed using adhesives. These adhesives ensure a secure fit and help maintain the vehicle’s integrity.

Conclusion

Auto glass making is an interesting process. It involves several key steps. Sand, soda ash, and lime are melted. Then, the glass is formed and cooled. Quality checks ensure safety. Next time you see a car window, remember its journey.

Understanding this process helps appreciate auto glass. It’s a blend of science and skill. We hope you found this guide useful. Thanks for reading!

As an Amazon Associate, I earn from qualifying purchases